Researchers in QIBEBT, China have focused on novel pretreatment methods to improve corn stalk degradation by forceful delignification for enhanced biomethanation. The findings revealed that AHP-LiCl/DMAc pretreatment improved accumulative methane yield by forceful delignification and effectively destroyed the structure of cellulose. Overall, this investigation proved a promising pretreatment approach for enhancing the degradation of CS into reducing sugars and improving methane generation.

The researchers published these findings in Environmental Research and Applied Microbiology Biotechnology, respectively.

The Molecular & Microbial Engineering (MMBE) Group at Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences, led by Professor Fu-Li Li, Ph.D., aimed to utilize novel pretreatment method that could degrade corn stalk, while improving biomethane yield. A maximum methane yield of 318.6 ± 17.8 mL/g VS was obtained in the AHP-LiCl/DMAc-treated group, which was 40% and 10% higher than the methane yields of the untreated and AHP-treated groups, respectively. This finding shows that the ionic solvent LiCl/DMAc enhanced cellulose dissolution and improved enzymatic saccharification in fermentative bacteria without structural modifications.

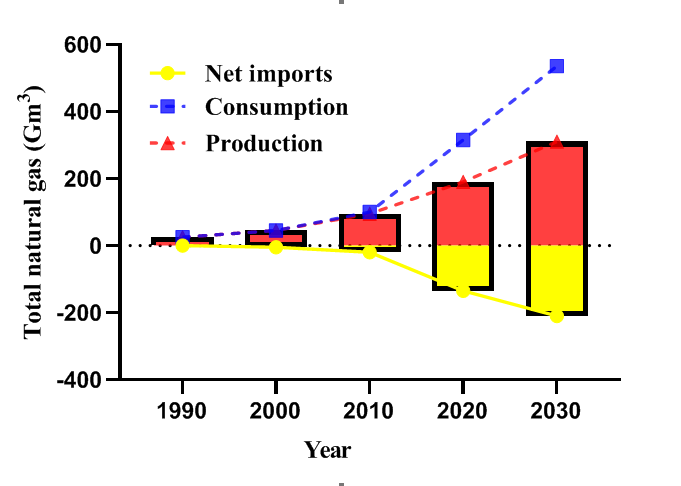

The team used this pretreatment method for enhanced bio-methane production, via transformation of cellulose to glucose followed by various fatty acid product and finally biomethane using sewage sludge containing specific microbial strain carrying useful degradation enzymes. Based on our results, the AHP-LiCl/DMAc treated group of corn stalk enhances 41% of biomethane from un-treated group, which is a huge difference from previously applied pretreatment strategies. On the other hand, aaccording to the China Natural Gas demand survey, the total natural gas consumption and import in 2018 were 283 Gm3 and 125.4 Gm3, respectively. The demand is much higher than the >300 Gm3/year consumption in 2020 (Fig 1). So we think our study is a huge contribution for the whole world in general and specifically China’s biogas industry, corresponding author, Ming LU said.

Fig. 1. Total natural gas consumption 213.6 Gm3, import 81.8 Gm3; 2020: demand >300 Gm3 /year.

For better pretreatment methodologies utilization, Dr. LU have discussed more biological, chemical and physical pretreatment methods in a review article in Applied Microbiology and Biotechnology published recently.

The authors stated that cellulase, hemicellulose and lignin degradation enzymes, the efficient bio-catalyst, could efficiently convert the lignocellulosic biomass into sugars that could be further processed into bio-fuels, bio-chemical and bio-material for human requirement. The utilization and conversion of cellulosic biomass has great significance to solve the problems such as environmental pollution and energy crisis. Lignocellulosic materials are widely considered as important sources to produce sugar streams that can be fermented into ethanol and other organic chemicals. Pretreatment is a necessary step to overcome its intrinsic recalcitrant nature prior to the production of important biomaterial has been investigated for nearly 200 years. Emerging research has focused in order of economical, eco-friendly and time-effective solutions, for large-scale operational approach. These new mentioned technologies are promising for lignocellulosic biomass degradation in a huge scale biorefinery.

Nasir Ali, Ming Lu and Fu-Li Li

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

E-mail: lvming@qibebt.ac.cn (ML);lifl@qibebt.ac.cn (FL)

News

News